Glass Tread Stairs and Glass Balustrade Stairs: Modern Architectural Elegance

Glass tread stairs and glass balustrade stairs have emerged as sought-after centerpieces in contemporary architecture, combining sleek transparency with reliable structural performance. These modern stairs exemplify the fusion of form and function – turning an everyday stairway into a luminous design feature without compromising on safety. For architects, interior designers, and remodeling contractors, understanding the value, specifications, and installation of these architectural stairs is key to successfully integrating them into luxury homes, cutting-edge retail stores, and stylish hospitality venues. Below, we delve into the architectural appeal, engineering requirements, material integrations, and project workflow for glass stair systems, offering a comprehensive guide to specify and implement these stunning staircases.

Architectural Appeal and Design Versatility

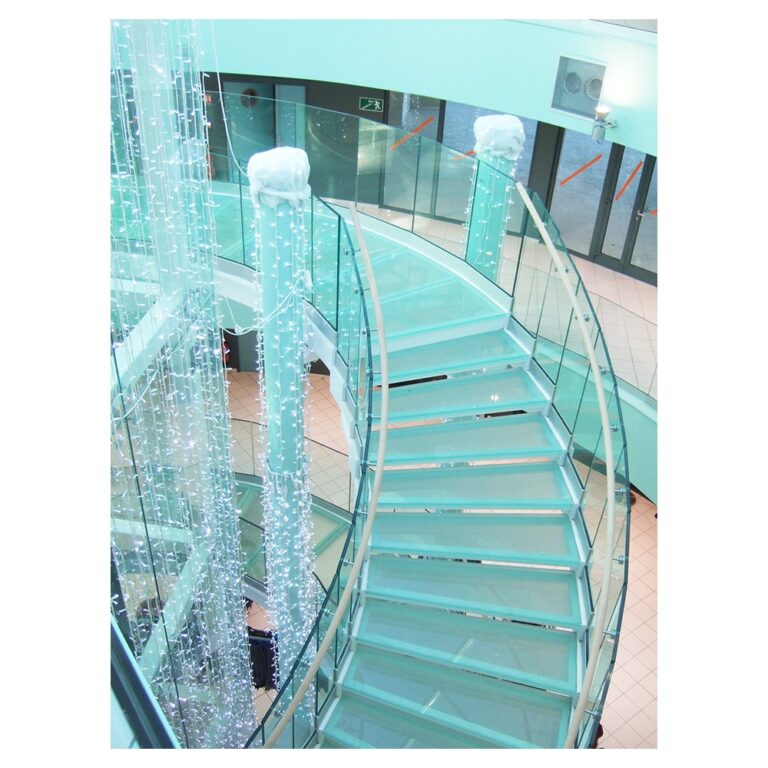

An illuminated spiral staircase with glass treads and a curved glass balustrade showcases how a modern glass stair serves as a sculptural centerpiece that amplifies light and space in an interior. The visual allure of glass stairs lies in their ability to open up sightlines and fill spaces with light. With transparent treads and railings, a glass staircase can make an interior feel larger, airier, and more connected than a traditional closed stair would. The glass components lend a clean, minimalist aesthetic that complements open-plan layouts and contemporary design styles. In many projects, the staircase becomes a functional art piece – a conversation starter that anchors the space with modern drama and elegance.

Design versatility is another hallmark of glass tread stairs. Each installation is custom-tailored, allowing for a range of striking configurations: floating stairs, dramatic helical spirals, sleek straight runs, or even cantilevered steps that appear to hover in mid-air. Glass staircases can incorporate creative features like LED lighting recessed in treads or handrails, causing the steps to glow after dark and further enhancing the “wow factor.” Architects can specify clear low-iron glass for maximum transparency or choose frosted/etched finishes for a subtle translucence that adds privacy and texture. The flexibility in form – from frameless all-glass designs to hybrids that pair glass with metal accents – means these stairs can be adapted to fit the character of high-end residences as well as chic commercial spaces. Ultimately, a well-designed glass stair not only serves its practical purpose but also elevates the ambiance of modern interiors, aligning with design-forward trends that emphasize openness and innovation.

Engineering and Safety Specifications

Beneath their beauty, glass staircases are rigorously engineered to meet strict structural and safety standards. Laminated safety glass is typically used for the treads (walking surfaces), consisting of multiple sheets of tempered glass bonded together with a robust interlayer. This construction ensures that even if a tread were to crack, the glass fragments remain trapped in place, avoiding a sudden failure. Building codes in the U.S. (e.g. IBC requirements) mandate laminated glass for weight-bearing stair treads and often for any glass used in guards or balustrades. The typical thickness of a laminated glass stair tread ranges from about 1 to 2 inches, depending on the span and support, providing the stiffness and strength needed for daily use. Structurally, these treads are engineered to support live loads comparable to conventional stairs – commonly at least 100 pounds per square foot (psf) – without excessive deflection. In practice, manufacturers test glass stair panels to withstand heavy foot traffic and concentrated loads, ensuring they perform as reliably as steel or wood steps.

Safety is paramount in the specification of glass tread stairs and glass balustrade stairs. All glass components must be safety glazing (tempered or laminated) that is many times stronger than ordinary glass and designed to fail safely (i.e. no dangerous shards). Glass balustrade panels, which act as the guardrails, are typically made of either tempered glass or laminated glass and must resist the lateral forces required by building codes for railings. This means the balustrade can withstand people leaning on it or even an impact, all while maintaining a slim, transparent profile. To address slip concerns on glass stair treads, manufacturers apply specialized anti-slip treatments on the top surface. Options include acid-etched patterns, ceramic frit coatings, or translucent non-slip strips that add traction without obscuring the glass clarity. These treatments help the glass treads achieve slip resistance comparable to other flooring (often targeting a coefficient of friction of ~0.6 wet/dry, per ASTM standards). Additionally, most jurisdictions require a graspable handrail alongside the glass balustrade for users to hold onto; this handrail is often a slender wood or metal rail that complements the sleek look while meeting code height and continuity rules. With proper specifications in thickness, lamination, support framing, and surface finish, a glass staircase can be just as safe and code-compliant as any traditional stair system, merging transparency with peace of mind.

Integrating Glass with Steel and Wood Systems

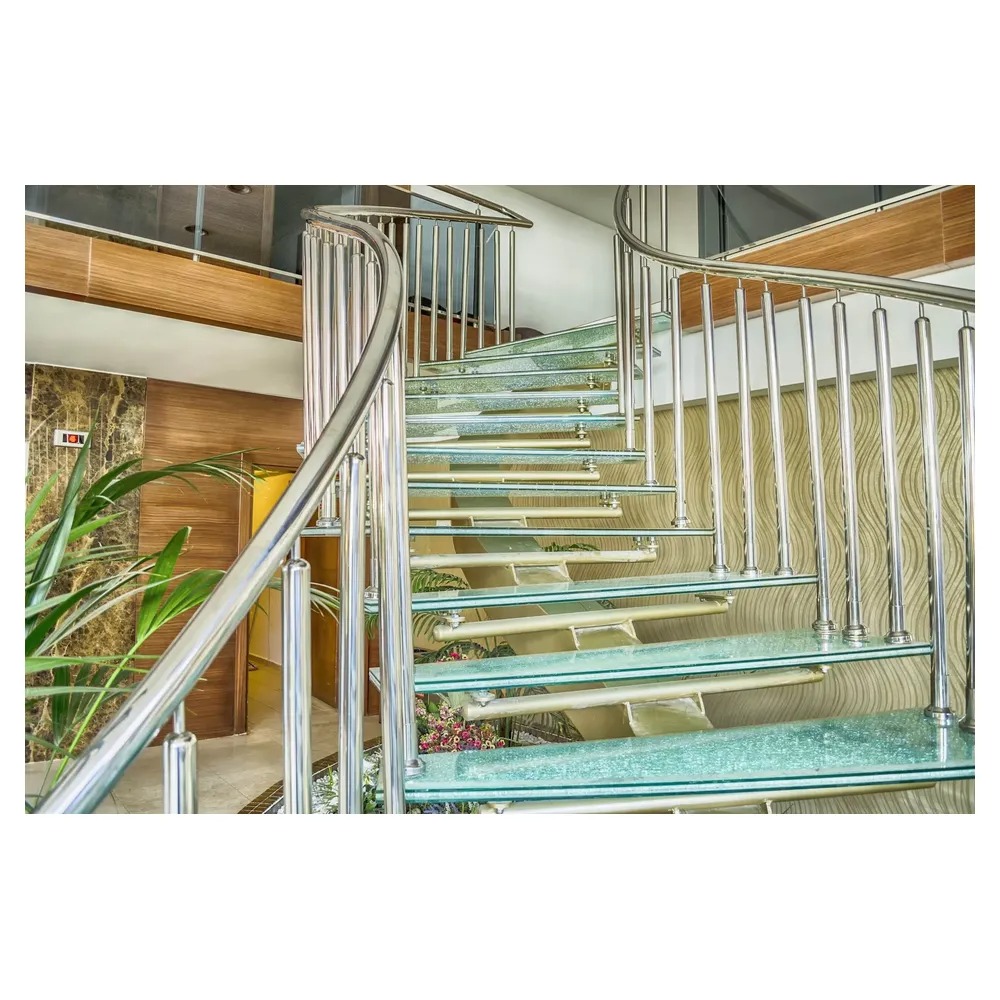

A critical aspect of designing glass stairs is how the glass elements integrate with structural supports. In practice, glass treads and panels are not floating magically – they rely on carefully engineered metal or wood frameworks to carry loads. Most commonly, stainless steel or structural aluminum components are used to create a secure backbone for the glass. For example, a contemporary design might use steel stringers (the support beams along each side or center of the staircase) to cradle each glass tread, achieving a floating effect while concealing attachments for a clean look. These stringers can be exposed as a design feature in an industrial-chic style, or hidden within walls for a truly frameless aesthetic. Glass railing panels are typically anchored with metal fittings as well – one popular method is mounting the balustrade panels into slim floor channels or on discreet standoff pins bolted to the stringers or floor structure. This avoids bulky framing and lets the glass sheets act as the transparent guardrail.

Glass stair components can also be successfully combined with wood structures, blending modern glass with traditional warmth. In renovation projects, it’s even possible to retrofit glass treads onto an existing wooden staircase. One case in point involved replacing old stair steps with 1.5-inch thick textured glass panels mounted on the original wood stringers – yielding a stunning transformation without rebuilding the entire stair framing. Likewise, a wood handrail can be paired atop glass balustrade panels to soften the look and provide a comfortable grip, marrying contemporary transparency with classic material. According to industry experts, glass stairs “combine glass treads with a metal or wood frame” by design, leveraging the strength of those substrates to support the glass. The key is collaborating with engineers and fabricators to detail the connections: whether using stainless steel brackets, through-glass bolts, or embedded hardware, each glass piece must be securely tied into the support structure. When executed properly, the integration of glass with steel or wood achieves an elegant balance – the stair feels light and open, yet it is supported by an underlying framework that ensures stability and longevity.

From Design Fabrication to Installation: Workflow and Best Practices

Because of their custom nature, glass tread stairs require careful planning and teamwork from the initial design through fabrication and installation. The process typically begins with a design consultation between the architect/designer and a specialized stair manufacturer or supplier. Every project is one-of-a-kind – dimensions, shapes, and mounting conditions are tailored to the building – so early collaboration with experienced engineers is essential. The stair supplier will usually provide detailed drawings, structural calculations, and specifications for approval, ensuring the design will meet both the client’s vision and code requirements. Engaging a qualified stair manufacturer from the outset helps in selecting the right materials (glass type, thickness, interlayer, metal grades) and confirming the support conditions needed for the glass stair system. Top manufacturers often act as partners in the project, offering end-to-end support at every step, from design conceptualization to final installation. This level of involvement streamlines coordination among the architect, structural engineer, and contractor, so that by the time the stair components are fabricated, all the critical details (anchorage points, tolerances, backing structure) have been accounted for.

Fabrication of glass stair components is a precise operation handled by expert craftsmen. The glass panels are cut to exact dimensions, edges polished crystal-smooth, and then laminated in climate-controlled conditions for optimum strength. Metal parts – whether steel stringers, brackets, or fittings – are custom-fabricated and often pre-drilled to align perfectly with the glass anchoring hardware. Before delivery, reputable stair manufacturers will typically test-fit or at least thoroughly inspect all parts to verify quality. Then comes the installation phase, which must be executed by skilled installers familiar with glass construction. It’s frequently noted that installing a complex glass staircase is not a DIY job – it demands the input of structural engineers and precision from seasoned installers to ensure everything lines up safely. On site, the team will use specialized lifting equipment (such as suction cups, cranes or hoists) to maneuver the heavy glass treads and balustrade panels into place without damage. Each piece is then secured per the engineered plan, whether that involves bolting through the glass to the stringers, tightening clamp rails, or grouting panels into a floor channel. Throughout this process, close attention is paid to alignment and level; even minor misalignments can affect the stair’s stability or visual perfection. Clear communication and coordination between the design team, fabricator, and site crew is vital for a smooth installation. When done correctly, the result is a flawless fit – the glass stair integrates seamlessly into the building, ready for final inspections and many years of use.

Modern Applications in Residential, Retail, and Hospitality Design

Glass staircases are synonymous with design-forward interiors and are increasingly featured in high-end projects across various sectors. Below are a few key applications where glass tread stairs and glass balustrade stairs add unique value:

- Luxury Residential: In upscale homes, a glass stair serves as a stunning focal point that elevates the overall interior design. Homeowners and architects often choose floating glass stairs to create an open, airy transition between levels, showcasing a taste for innovative, modern style. The transparency of glass treads allows light to filter through multiple floors, making the living space feel larger and more interconnected. In a grand foyer or duplex penthouse, a well-executed glass staircase is a conversation piece that signifies contemporary elegance and craftsmanship.

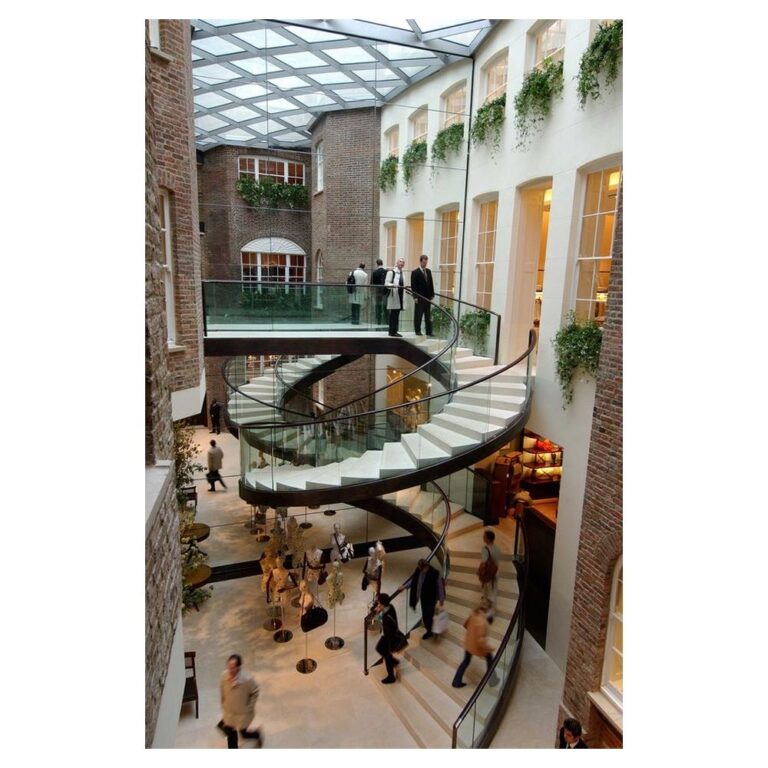

- Retail & Showrooms: Many luxury retail stores and showrooms incorporate glass stairs to impress customers and encourage exploration of multi-level spaces. With clear treads and minimal structure, these stairs keep sightlines open to merchandise displays, creating an inviting flow through the store. A flagship boutique might use a dramatic glass stair as an architectural emblem of the brand – the journey upstairs becomes a memorable experience in itself, reinforcing a cutting-edge, upscale brand image. Beyond aesthetics, the robust laminated glass and steel support ensure the stair can handle heavy foot traffic in a commercial setting while maintaining its pristine appearance.

- Hospitality & Commercial: Hotels, restaurants, and corporate offices utilize glass staircases to convey a forward-thinking, luxurious atmosphere. In a hotel lobby or a chic restaurant, a glass balustrade stair can visually connect different levels of the space, allowing decor and lighting to harmonize throughout. Guests are often struck by the openness and modernity that a glass stair imparts – it signals that the venue is stylish and sophisticated. From a practical standpoint, these installations are engineered to meet stringent safety codes for public occupancy, including requirements for fire-rated materials and accessibility where applicable. When paired with features like accented lighting or architectural steel details, glass stairs in commercial environments embody both innovation and professionalism.

In all of these environments, glass tread and balustrade stairs create a balance of transparency, light, and structural finesse that transforms the ambiance. They enable designers to achieve a bold visual impact – floating lines and luminous materials – while still delivering the functionality and safety expected of a staircase.

Conclusion and Call to Action

Glass tread stairs and glass balustrade stairs represent the perfect synergy of modern design and structural engineering. They introduce light-filled elegance and a high-tech aesthetic to interiors, all while meeting the same load-bearing and safety standards as traditional stair constructions. For architects and builders looking to make a statement with a modern stair design, partnering with an experienced stair manufacturer or supplier is the key to success. With expert guidance, these bespoke staircases can be tailored to any space – whether it’s a custom home, a retail flagship, or a cutting-edge hospitality project – and executed to the highest quality. If you’re considering a glass staircase for your next project, we invite you to reach out for a consultation. As a leading stair supplier, our team offers custom design support, engineering expertise, and fabrication resources to turn your vision into reality. From initial concept through installation, we ensure every glass tread and balustrade is crafted and delivered to perform beautifully. Contact us today to discuss your project requirements or to request a quotation – let us help you elevate your interior with a stunning glass stair solution that defines luxury and innovation.